"Clown Shoe Pilot" (csp)

"Clown Shoe Pilot" (csp)

02/16/2016 at 00:34 ē Filed to: None

0

0

17

17

"Clown Shoe Pilot" (csp)

"Clown Shoe Pilot" (csp)

02/16/2016 at 00:34 ē Filed to: None |  0 0

|  17 17 |

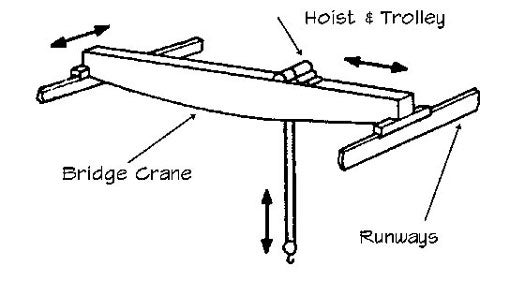

Iím planning a shop building, and one of the things I am building in is a bridge crane. Iíve got a list of parts and measurements. I need someone who knows how to evaluate a design and tell me if itís going to crater on me or not. I also need a recommendation for the bits that are going to hold the whole mess up in the air.

Anyone up to the task?

bob and john

> Clown Shoe Pilot

bob and john

> Clown Shoe Pilot

02/16/2016 at 00:38 |

|

iím a mech eng student, but iím willing to try it.

this building is for your personal use?

Clown Shoe Pilot

> bob and john

Clown Shoe Pilot

> bob and john

02/16/2016 at 00:58 |

|

Yes, personal use. Iím building a bridge crane with a proposed max load on the hoist of 1 ton. The hoist and end trucks are rated for 1 ton, so Iím not worried about that.

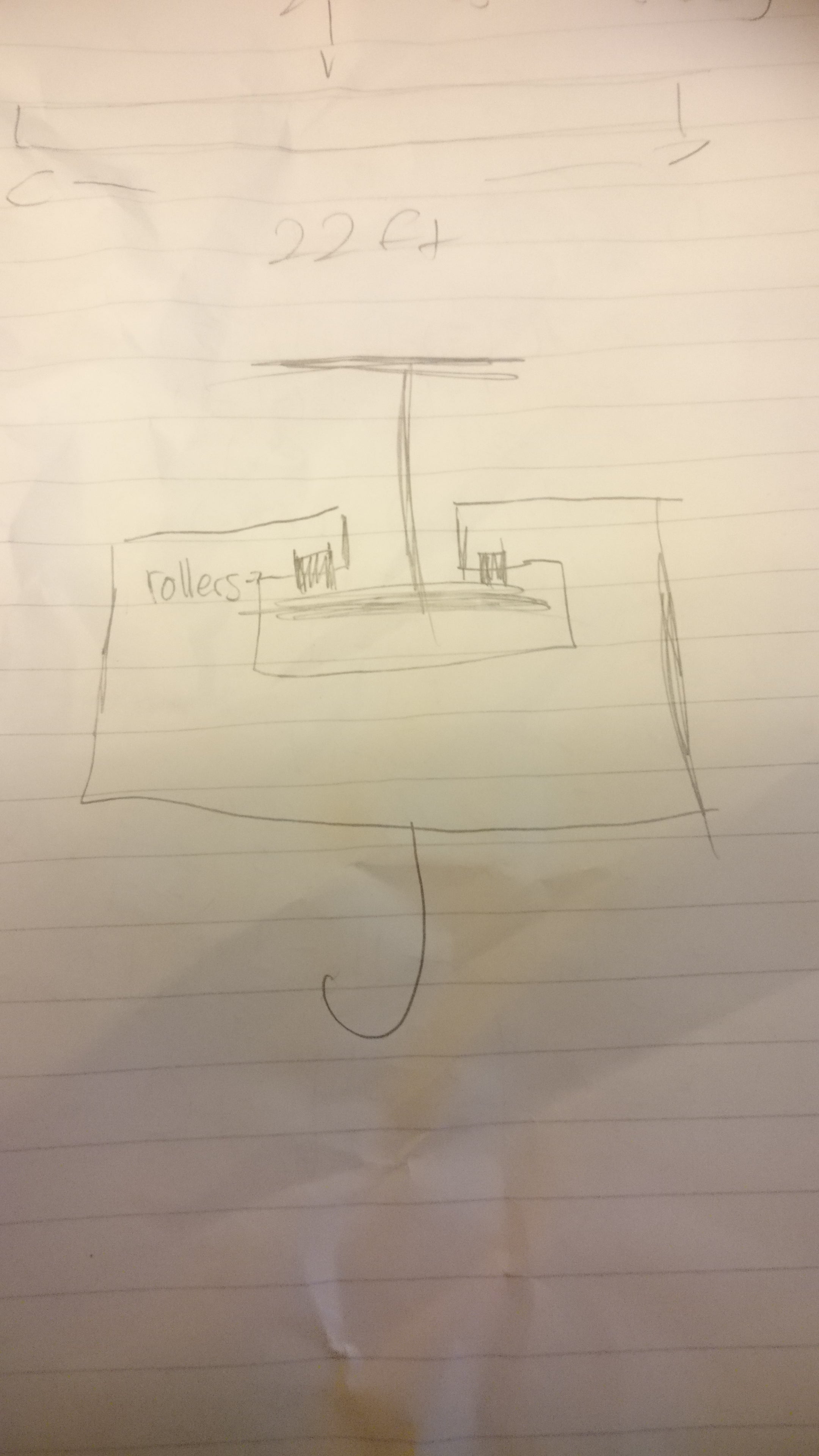

My runway beams will be 30 feet long and set 22 feet apart. The bridge beam is 22 feet long. All beams are S6x17.25 standard I beam.

End trucks - http://www.harringtonhoists.com/products/pdf/cÖ

What I want to know is:

1) Is S6x17.25 beefy enough for the bridge beam? The point load in the center of the bridge beam could be as much as 2100 pounds and itíll be moving around.

2) Is S6x17.25 beefy enough for the runway beams? The bridge beam + load would max out at 2750 pounds. That could all be in the center of the span, and if the hoist trolley was at either edge of the span, it could put more weight on a single runway beam.

3) would 4" square tube be sufficient to hold everything up in the air? Assume there will also be some chunks of steel holding the runway beams at their set width.

Let me know if you need more info.

bob and john

> Clown Shoe Pilot

bob and john

> Clown Shoe Pilot

02/16/2016 at 01:14 |

|

did you account for the weight of the actual hoist mechanism and cable?

Clown Shoe Pilot

> bob and john

Clown Shoe Pilot

> bob and john

02/16/2016 at 01:16 |

|

Yes. The end trucks are 107# each, and the hoist + chain is 65#

bob and john

> Clown Shoe Pilot

bob and john

> Clown Shoe Pilot

02/16/2016 at 01:23 |

|

Okay. How do you plan on holding the hoist itself?

Something like this?

Bman76 (no it doesn't need a WS6 hood) M. Arch

> Clown Shoe Pilot

Bman76 (no it doesn't need a WS6 hood) M. Arch

> Clown Shoe Pilot

02/16/2016 at 01:25 |

|

Iím getting KL/r max errors running that calculation, suggesting W6x15.

Clown Shoe Pilot

> bob and john

Clown Shoe Pilot

> bob and john

02/16/2016 at 01:30 |

|

exactly. the hoist/trolley is a single assembly that is underhung on the bridge beam.

http://www.harringtonhoists.com/products/pdf/cÖ

bob and john

> Clown Shoe Pilot

bob and john

> Clown Shoe Pilot

02/16/2016 at 01:31 |

|

awesome.

its about 1:30am here right now. Iíll get back to you in the morning on this okay?

Clown Shoe Pilot

> Bman76 (no it doesn't need a WS6 hood) M. Arch

Clown Shoe Pilot

> Bman76 (no it doesn't need a WS6 hood) M. Arch

02/16/2016 at 01:38 |

|

Can you re-word that? I THINK youíre saying that the S6x17.25 beam fails some test and that W6x15 would pass if substituted. If yes, What about W6x16? The flange width on the x15 beam is too big for the carriage on the trolly. I have more freedom in the beam height than in flange width.

What is KL/r max?

Clown Shoe Pilot

> bob and john

Clown Shoe Pilot

> bob and john

02/16/2016 at 01:39 |

|

sure, no sweat

Bman76 (no it doesn't need a WS6 hood) M. Arch

> Clown Shoe Pilot

Bman76 (no it doesn't need a WS6 hood) M. Arch

> Clown Shoe Pilot

02/16/2016 at 01:48 |

|

Based on some software, itís kinda thin side to side, KL/r is longitudinal twisting. The software is suggesting W6x15 to deal with that.

(Also, Iím an Arch grad student, so trust the engineers over me.)

Clown Shoe Pilot

> bob and john

Clown Shoe Pilot

> bob and john

02/16/2016 at 02:01 |

|

Also, Iím using the end trucks as underhung, not top running. I donít thing that makes a difference but in case it does, now you know.

bob and john

> Bman76 (no it doesn't need a WS6 hood) M. Arch

bob and john

> Bman76 (no it doesn't need a WS6 hood) M. Arch

03/01/2016 at 17:31 |

|

KL/r is used for the column buckling IIRC

bob and john

> Clown Shoe Pilot

bob and john

> Clown Shoe Pilot

03/01/2016 at 18:25 |

|

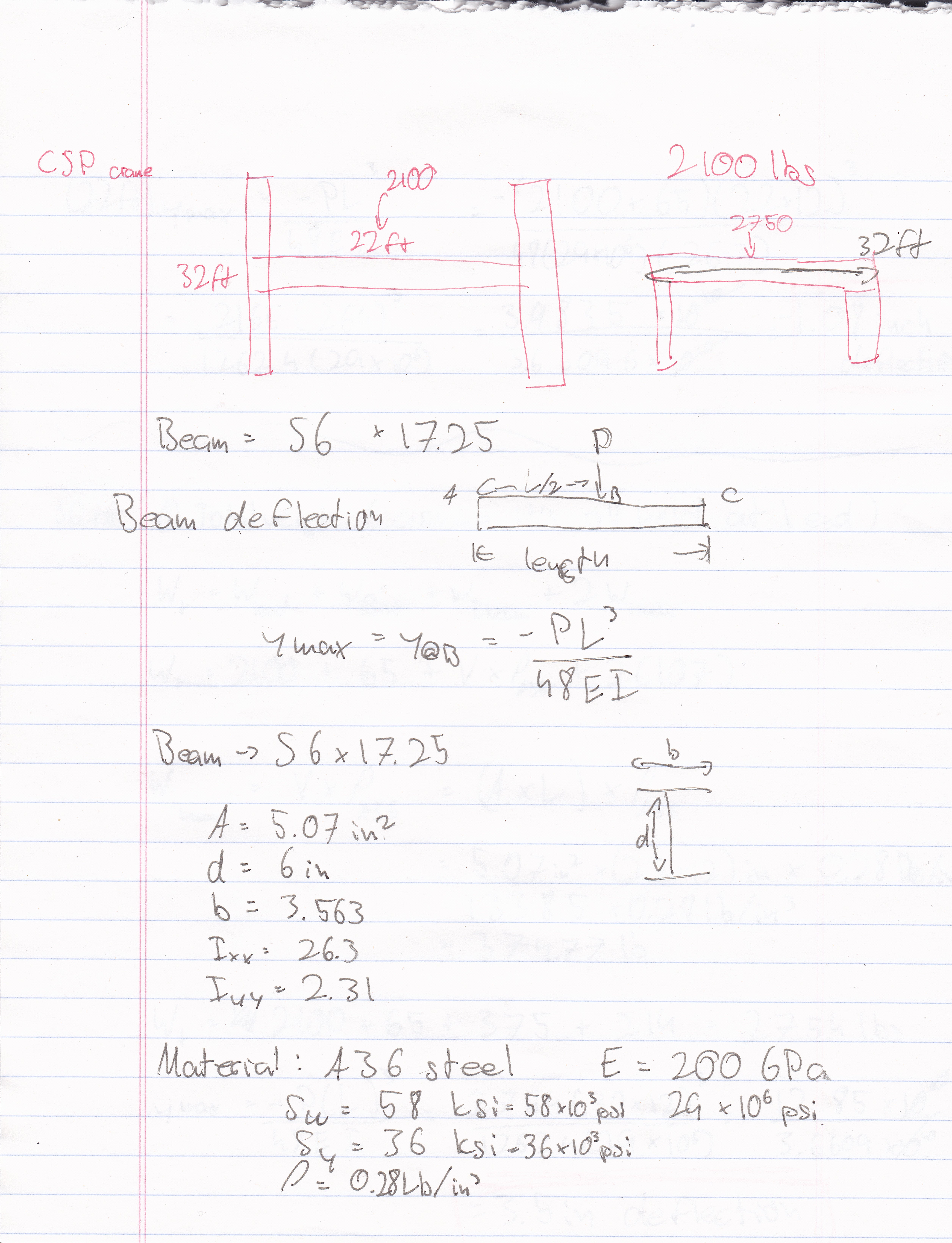

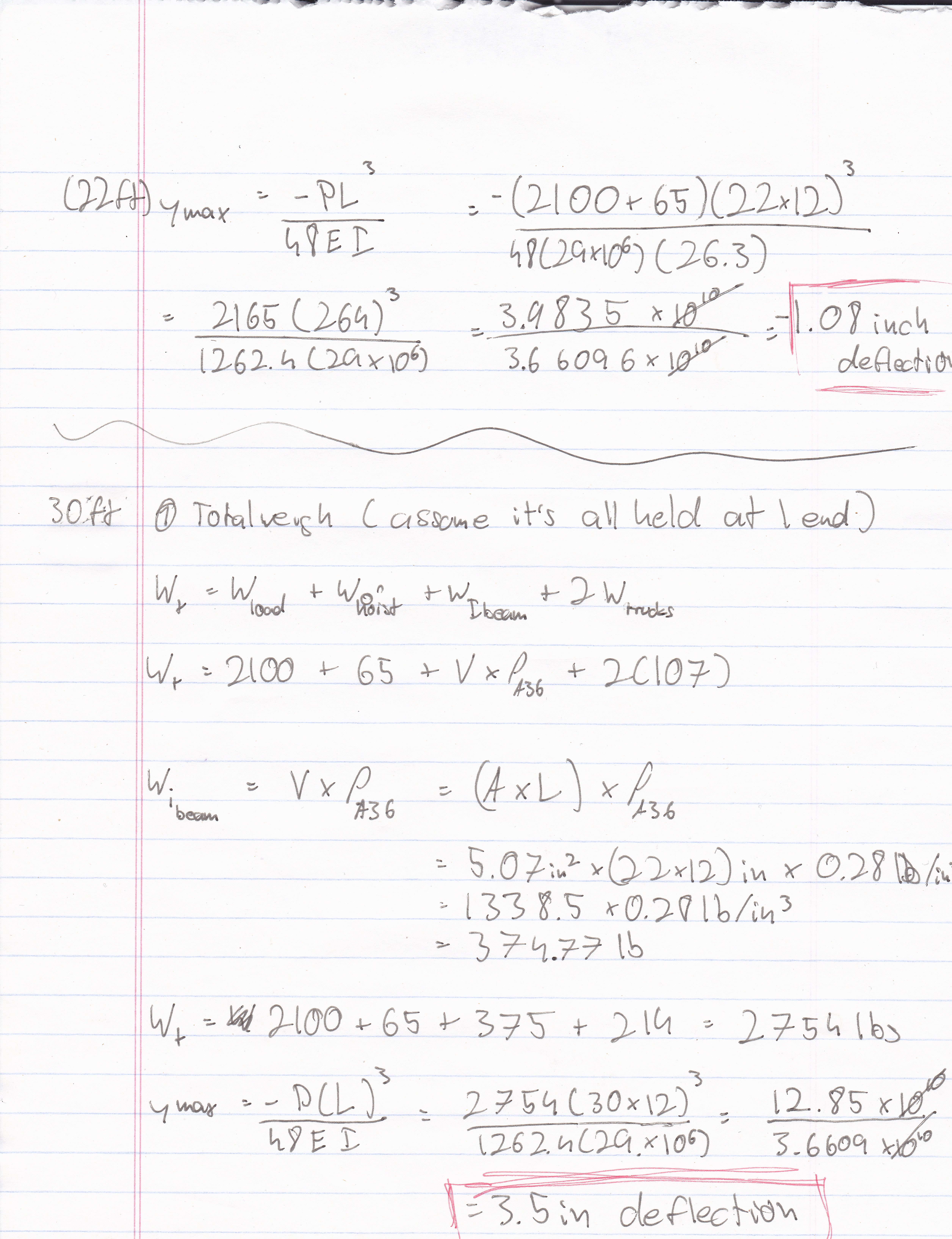

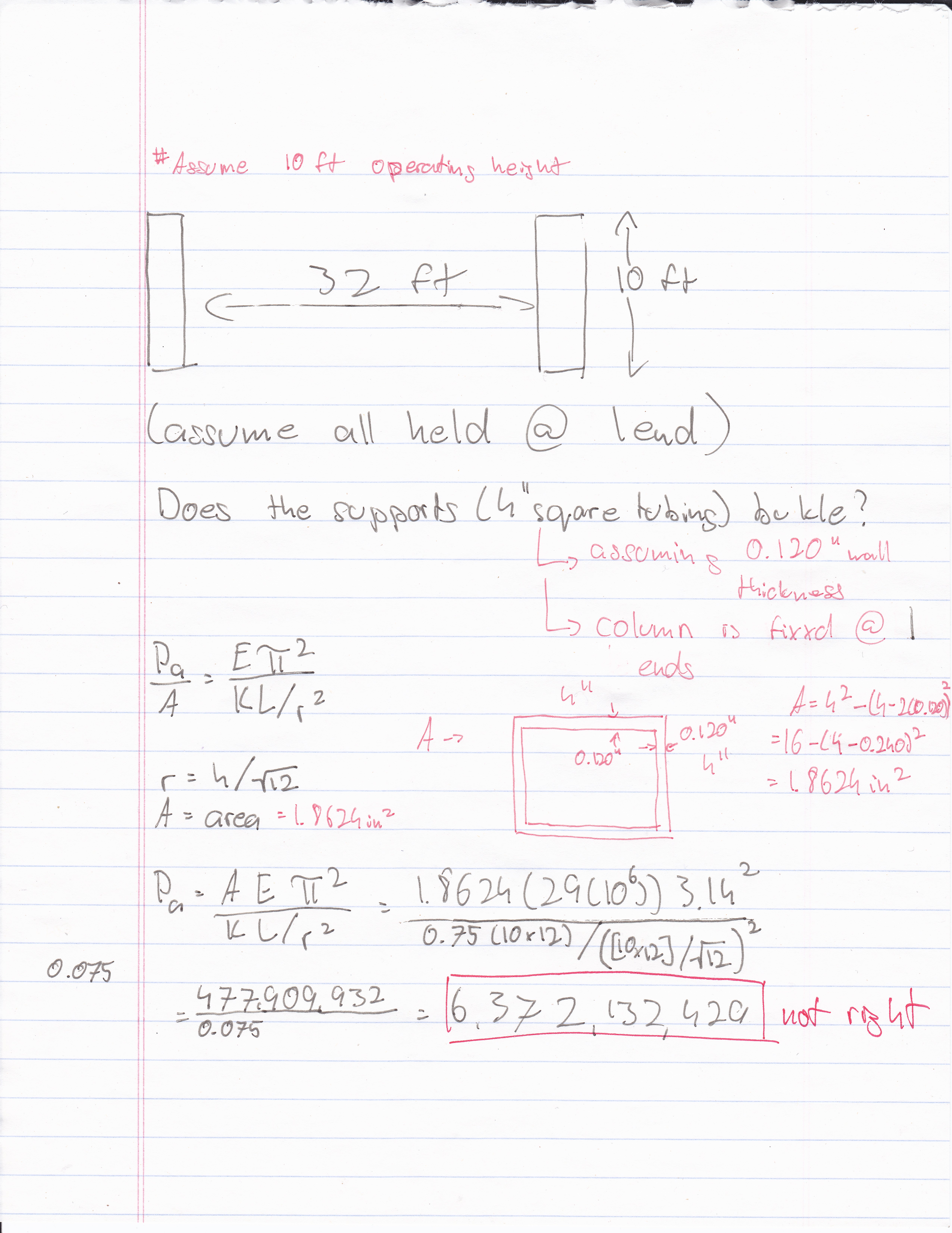

okay, so I did some basic calculations on it.

first page: just establishing some givens (beam, sizes, spans, etc etc)

note: I used A36 steel for my calculations

page 2: found the MAX deflection in the 22ft steel beam assuming a 2100lbs load and the hoist/chain combo of 654 lbs (for a total load of 2165lbs)

the max deflection in THAT beam is 1.08 inchs.

the bigger issues comes from the 32 ft spans. assuming one side would have to hold everything (the whole weight of the 22ft span, both trucks, the 2100lbs load and the hoist) your looking at 3.5 inchs of deflection. (over a 30 ft span)

so WORST case scenario you have 4.58 inch of deflection with a 2100lbs load. I dont know how often you plan on reaching this load, so i just took the worst case senario

(remember, i did all the calculations as if it was all supported by 1 beam)

here I wanted to find the max loading for the 4inch supports (assuming a 0.120" wall thickness)

I fucked something up here, and iím not entirely sure what.

If you want, i can go through this with one of my professors this week and see if i made a mistake/if the design is good.

Clown Shoe Pilot

> bob and john

Clown Shoe Pilot

> bob and john

03/01/2016 at 21:56 |

|

Sweet! Thanks!

Donít sweat the columns - I think Iím going to go w/ I beam for those too. The deflection numbers are interesting. I doubt Iíll ever load the thing up all the way and itíd be impossible to ever hit the worst case - to get one of the long beams to max deflection, Iíd have to put the hoist at one of the extremes of the short beam. If I do that, there wonít be any deflection on the short beam. To max out deflection on the short beam, the load has to be dead middle and that should spread the load pretty evenly between the two long beams.

One question I have - assuming length stays constant, does deflection vary linearly with weight? If Iím reading the math right, it looks like it does. Length is exponentially more important - doubling the length would increase the deflection by 8x.

bob and john

> Clown Shoe Pilot

bob and john

> Clown Shoe Pilot

03/02/2016 at 00:21 |

|

it does, but keep in mind you have to stay inside the allowed strain.

once a material bends too far, it wont go back to its original shape and its carrying capacity is now compromised. and then it bends further.

this was just a very basic going through to make sure the beams themselves could hold the weight. Iíll have to do some other calculations to see how they hold up in terms of strain from cyclic loading and if you end up ripping the hoist from the I-beam (if you want me to)

Clown Shoe Pilot

> bob and john

Clown Shoe Pilot

> bob and john

03/02/2016 at 08:56 |

|

If youíve got the time, Iíve got the beer.